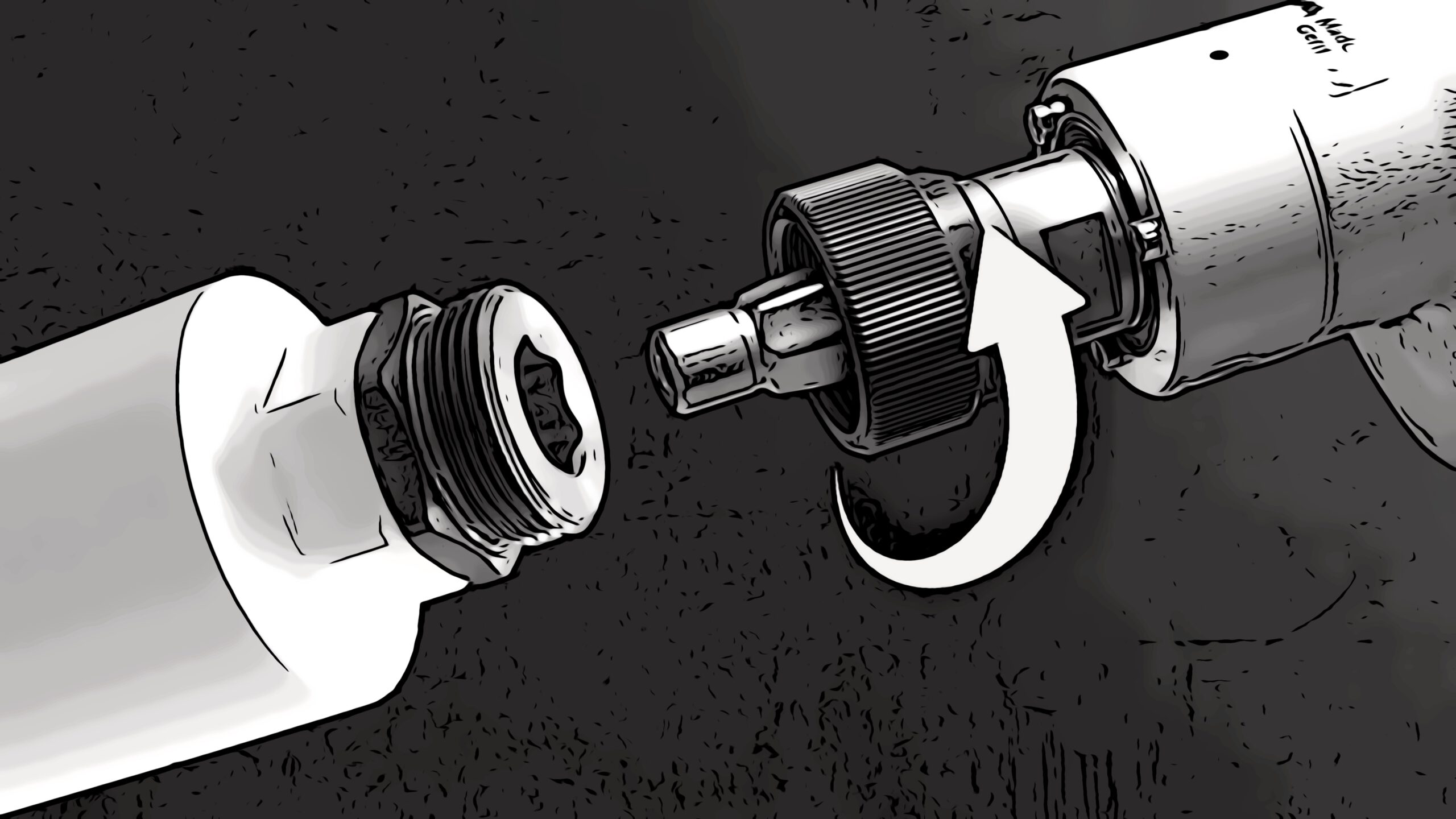

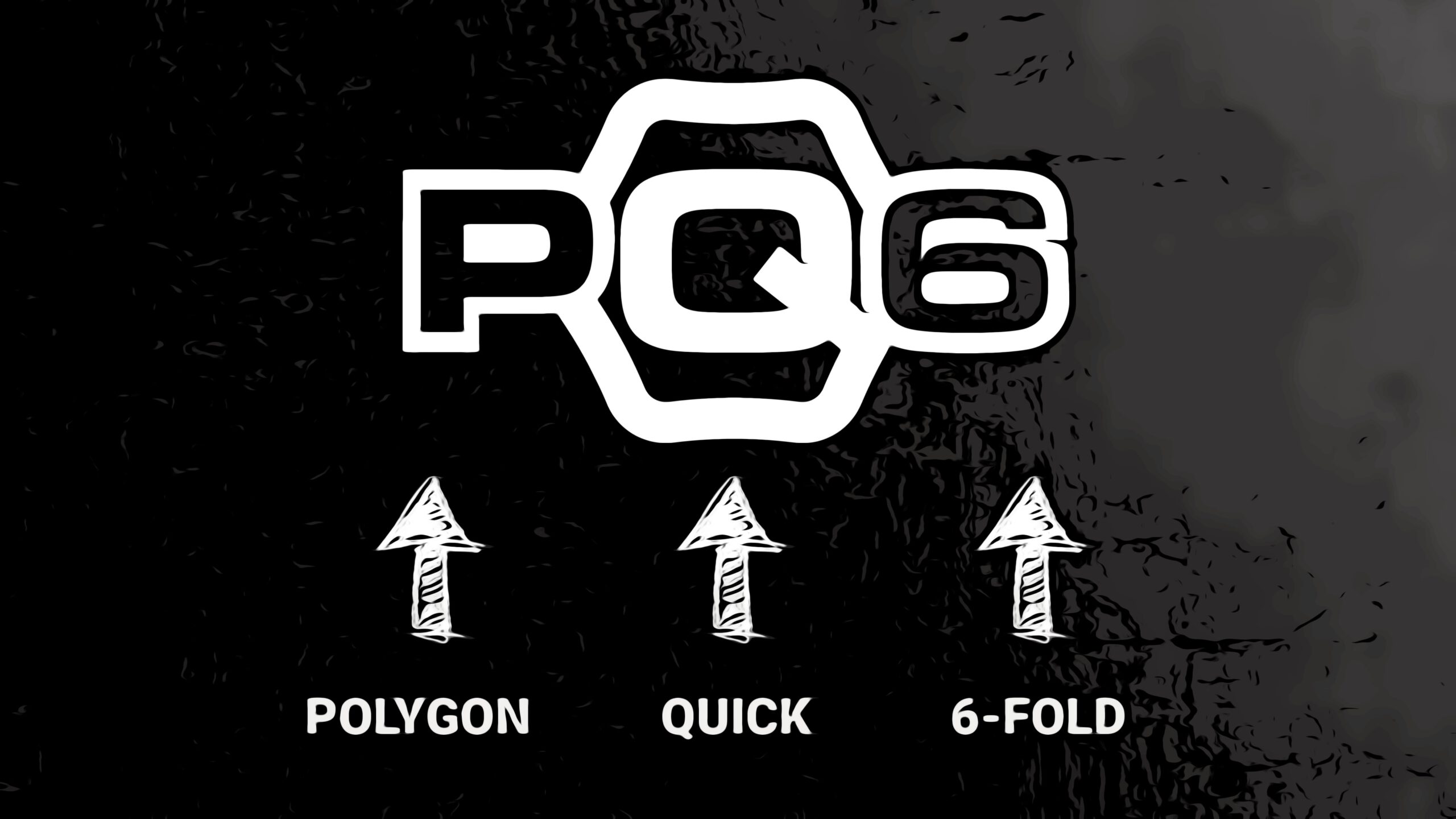

PQ6 – the new, tool-free connection system for core drills. It makes it so easy to change drill bits you will start to love it.

The new, hassle-free PQ6 drill bit connection saves you every day annoying and time-wasting usage of extra tools when mounting and dismounting core drill bits. From now on, searching and carrying additional tools for changing your core drill bits finally ends!